Basic Thread Terms – Part 2

Additional Terms

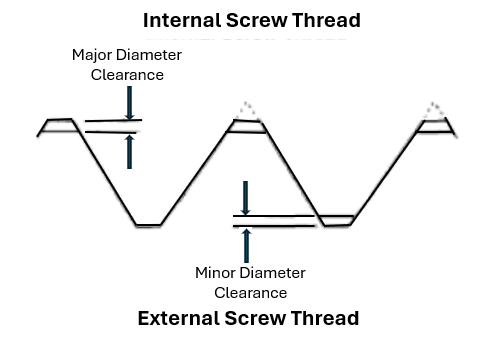

Major Diameter Clearance – The difference between the major diameter (crest) of the external thread and the major diameter (root) of the mating internal thread.

Minor Diameter Clearance – The difference between the minor diameter (crest) of the thread and the minor diameter (root) of the mating external thread.

Length of Engagement – The length that is engaged measured parallel to the axis when mating parts are assembled.

Symmetrical Thread Form – Any thread form having a basic design profile with equal crest and root truncation and equal flank angles. The unified thread form pictured has equal 30° flank angles and equal crest and root truncati

Truncation – The distance measured perpendicular to the axis between the theoretical sharp apex and actual flat at crest (or root). In the Symmetrical Thread form diagram the truncation is designated as “t”.

Unified Screw Thread Designations

UNC – Unified National Coarse series

UNF – Unified National Fine series

UNEF – Unified National Extra Fine series

UN – Unified National Constant Pitch series

UNS – Unified National special Diameter Pitch Combination

UNR – Unified threads having .108P – .144P root radius on external thread

UNJ – Unified threads having closely controlled .150P – .180P root radius on external threads and increased minor diameter on internal threads – used mainly on critical aeronautical applications

UNC – Unified National Coarse series

UNF – Unified National Fine series

UNEF – Unified National Extra Fine series

UN – Unified National Constant Pitch series

UNS – Unified National special Diameter Pitch Combination

UNR – Unified threads having .108P – .144P root radius on external thread

UNJ – Unified threads having closely controlled .150P – .180P root radius on external threads and increased minor diameter on internal threads – used mainly on critical aeronautical applications

Standard UNC and UNF thread sizes are generally preferred if they are suitable for the application. Taps, dies, chasers and other threading tools for them as well as thread gages are widely available from stock at lowest costs. If one or both components involve a commercial fastener (nut, screw or bolt, etc.), again, standard sizes are the most economical.